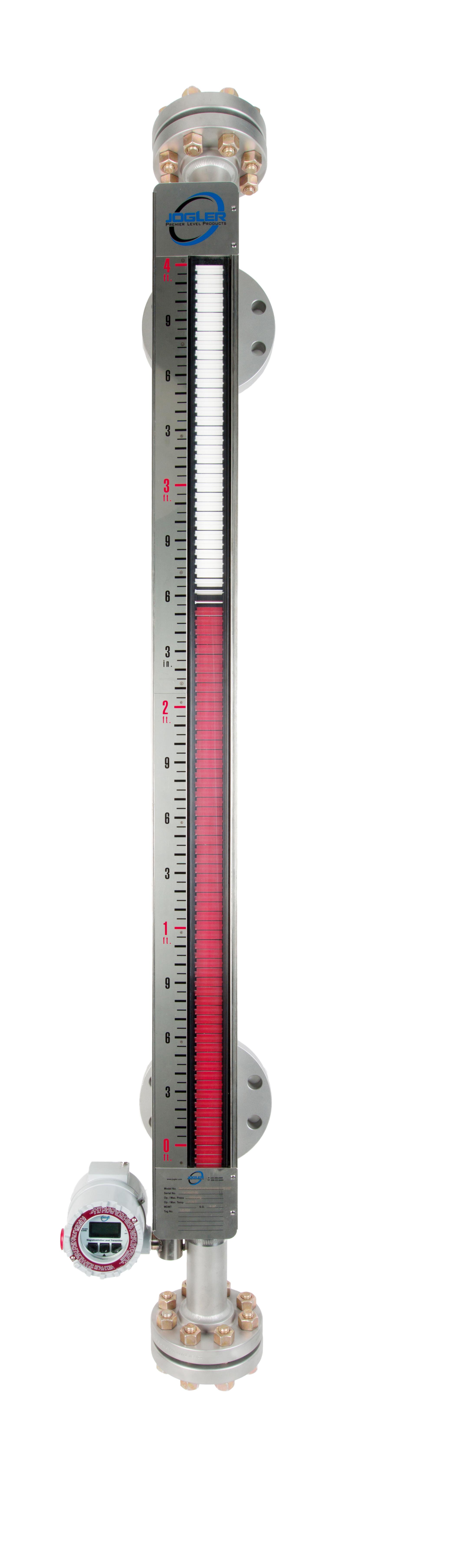

MODEL MGT-6000

Magnetostrictive Level Transmitter

The MGT-6000 Magnetostrictive Level Transmitter is a loop powered non-contact level measurement device that is mounted externally to a magnetic level gauge. Utilizing the magnetostrictive principle and time-of-flight calculations allow the MGT-6000 to provide a fast and accurate measurement of float position and, ultimately, liquid level in the gauge. Vibration-isolating elastomeric bushings ensure continuous operation in high vibration services.

2 wire, loop powered (24VDC nominal)

LCD Display (4-20mA, %, in, and/or cm)

Generic HART communication

Quick-Cal function for simple recalibration

Isolated from process pressure, temperature, and vibrations

Long Measuring Lengths (up to 35ft)

Retrofit to most magnetic level gauges with no process interruption

Dual level outputs (total level and interface)

Epoxy-Coated Aluminum Enclosure

Class I, Division 1, Groups A, B, C, D

Class II and Class III, Division 1, Groups E, F, G

Class I, Division 2, Groups A, B, C, D

Class II and Class III, Division 2, Groups E, F, G

Intrinsically Safe Class I / II / III, Division 1, Groups A, B, C, D, E, F, G

NEMA 4X

MGT-6000 Theory of Operation: Click to expand

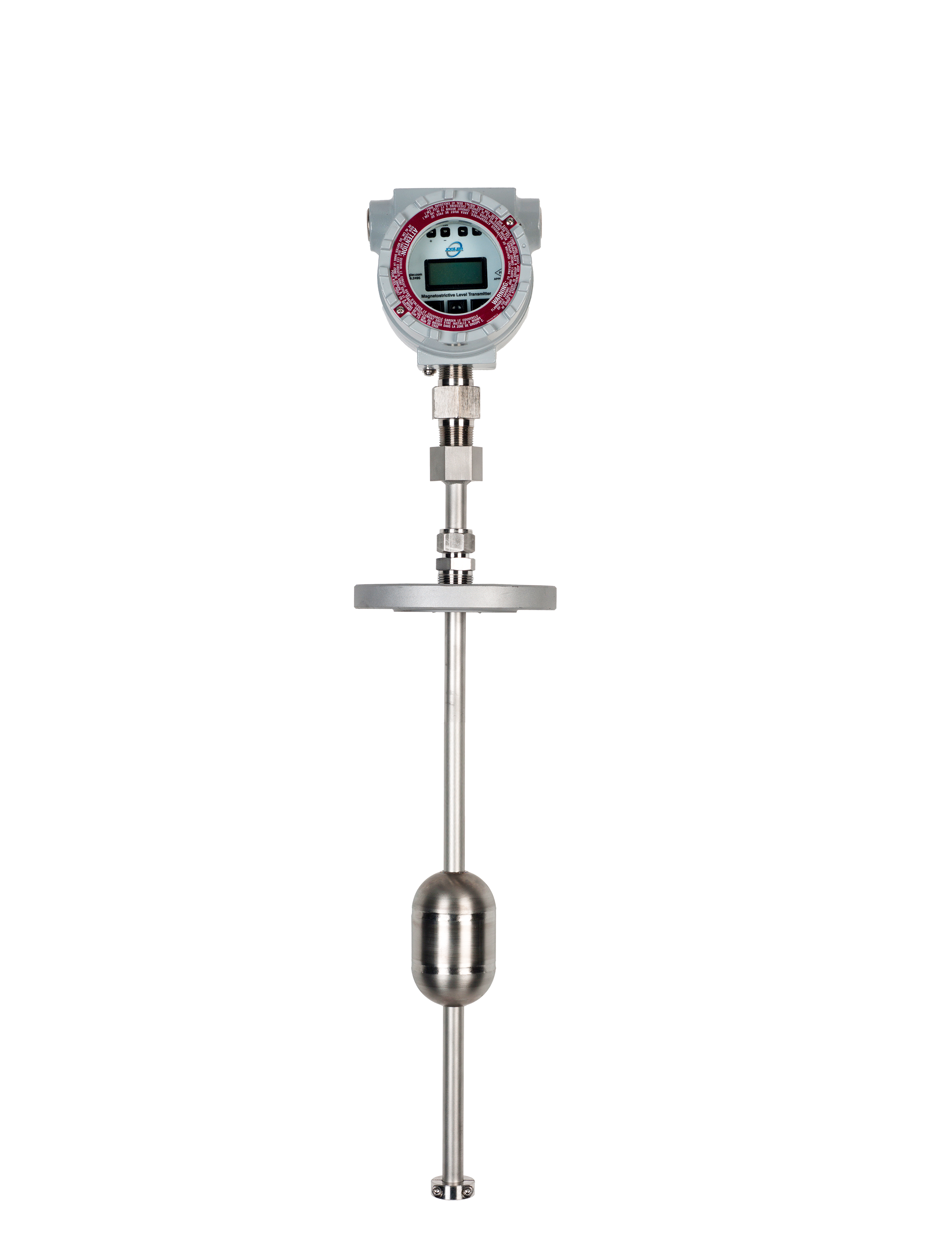

MODEL ILT-6000

Direct Insertion Magnetostrictive Level Transmitter

The ILT-6000 Direct Insertion Magnetostrictive Level Transmitter is a loop powered non-contact level measurement device that can be installed directly into a process vessel. Utilizing the magnetostrictive principle and time-of-flight calculations allow the ILT-6000 to provide a fast and accurate measurement of float position and, ultimately, liquid level in the gauge. The ILT-6000 is installed in an isolation well assembly allowing the transmitter to be removed, serviced, or replaced with no process interruption.

2 wire, loop powered (24VDC nominal)

LCD Display (4-20mA, %, in, and/or cm)

Generic HART communication

Quick-Cal function for simple recalibration

Isolated from process pressure

Long Measuring Lengths (up to 35ft)

Isolation Well assembly

Dual level outputs (total level and interface)

Epoxy-Coated Aluminum Enclosure

Class I, Division 1, Groups A, B, C, D

Class II and Class III, Division 1, Groups E, F, G

Class I, Division 2, Groups A, B, C, D

Class II and Class III, Division 2, Groups E, F, G

Intrinsically Safe Class I / II / III, Division 1, Groups A, B, C, D, E, F, G

NEMA 4X

ILT-6000 Theory of Operation: Click to expand